委托生产

我们拥有长年累月所积累下来的合成技术,可以随需求满足从工艺开发到GMP委托生产。

GMP少量生产设备的完备,结合上我们已经拥有的GMP大型设备及多功能性设备,

使得我们能够灵活应对从数百克到大批次的生产。

基于ICH-GMP的标准,通过DMF和CEP的注册,FDA审查等经验,使得我们拥有了过硬的品控管理体制,

可以提供让客户满意的委托生产服务。

另外,我们在EHS投资方面也是不遗余力。

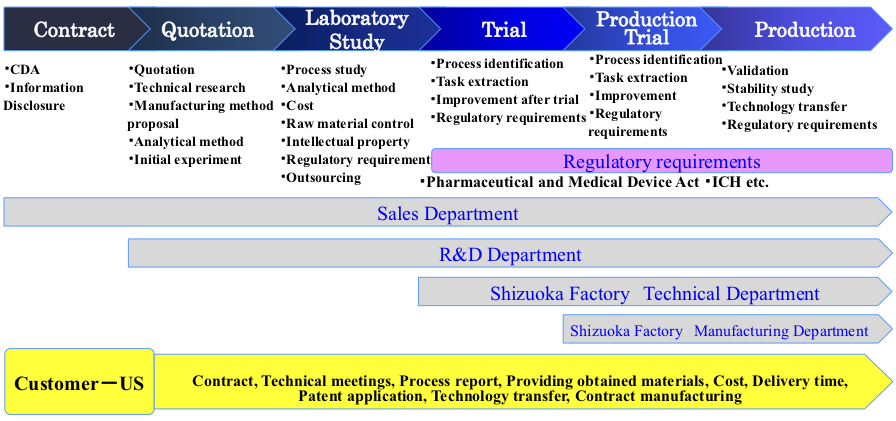

Contract Manufacturing Flow

Main Facilities

Pilot Plant

| Facilities | Specification | Capacity | Quantity |

|---|---|---|---|

| Reactors Normal Pressure, -5~140℃(200℃) |

Glass Lining | 10L | 5 |

| Glass Lining | 300L | 5 | |

| 1,000L | 1 | ||

| Stainless | 300L | 3 | |

| 500L | 1 | ||

| Autoclave ~10kg/cm2, -5~140℃ |

Stainless | 200L | 1 |

| Vacuum Distilling Apparatus 3mmHg, ~200℃ |

Stainless | 200L | 1 |

| Centrifuge | Top emission type, Stainless | φ12 inches | 1 |

| φ20 inches | 2 | ||

| φ30 inches | 1 | ||

| Filter Separators | Pressurization, Stainless | 2 | |

| Reduced pressure, Stainless | 2 | ||

| Dryers | Shelf- fan dryer, Stainless-steel | 1 | |

| Shelf-type vacuum dryer, Stainless | 1 | ||

| Conical type vacuum dryer, Stainless | 30L | 1 | |

| Clean Room | Clean level: 100,000/ft3 Ventilation: 20 times/hr or more |

1 | |

| Freezer Medium -20℃ |

3600kcal/hr | 1 |

Commercial Plant

| Facilities | Specification | Capacity | Quantity |

|---|---|---|---|

| Reactors Normal Pressure~100mmHg, -5~140℃(200℃) |

Glass Lining | 2m3~10m3 | 41 |

| Stainless | 1m3~10m3 | 67 | |

| Ti clad | 2.5m3 | 2 | |

| Autoclaves ~10kg/cm2, -5~140℃ |

Stainless | 2m3~4m3 | 5 |

| Glass Lining | 4m3 | 1 | |

| Photo-reactor 600〜700nm |

Stainless Sodium Lamp |

1 | |

| Vacuum Distilling Apparatus 3mmHg, ~180℃, N=12 |

Stainless | 1m3~7m3 | 3 |

| Centrifuges | Bottom emission type, Stainless | φ24~55 inches | 5 |

| Top emission type, Stainless | φ24~55 inches | 21 | |

| Filter separators | Pressurization, Stainless | 18 | |

| Reduced pressure, Stainless | 29 | ||

| Reduced pressure, FRP | 1 | ||

| Dryers | Shelf-type fan dryer, Stainless | 22 | |

| Conical type vacuum dryer, Stainless | 2~2.5m3 | 6 | |

| Clinical type vacuum dryer, Glass Lining | 2m3 | 2 | |

| Nauta-type vacuum dryer, Stainless | 1m3 | 3 | |

| 2m3 | 5 | ||

| Mills | Pin mill, Stainless | 9 | |

| Hammer mill, Stainless | 3 | ||

| Power mill, Stainless | 1 | ||

| Feather mill, Stainless | 1 | ||

| Jet mill, Stainless | 1 | ||

| Clean Rooms | Clean level: 100,000/ft3 Ventilation: More than 20 times/hr |

Centrifuge rooms | 10 |

| Drying rooms | 11 | ||

| Milling rooms | 12 | ||

| Ice Maker | Stainless 2.4t/day | 1 | |

| Wastewater treatment | Activated sludge | ||

| Freezers | Medium -20℃ Inside -10 ~ -5℃ |

46kW | 16 |

Main Analytical Equipment (Shizuoka Factory)

We have necessary analytical equipment for product quality control.

We operate accordance with data integrity.

We can use the equipment of R&D in Tokyo depending on the customer’s requirements.

We operate accordance with data integrity.

We can use the equipment of R&D in Tokyo depending on the customer’s requirements.

| Equipment | Specification |

|---|---|

| HPLC | High and low pressure gradients Detector: UV, UV-VIS, RI |

| GC | Detector: FID Equipped with a head-space sample injection device |

| ICP-MS | Responding to elements subject to ICH-Q3D Step 4 Responding to organic solvents |

| FT-IR | 7800~350cm-1 |

| UV-visible spectrophotometers | 190~900nm |

| Karl Fischer moisture meter | Volumetric procedure Coulometric titration |

| Potentiometric titrator | pH 0.00~14.00 |

| Polarimeter | 589nm (Na) |

| Particle size distribution analyzer | Laser diffraction type(dry and wet), microscope type, air permeability method |

Main Reactions

Technologies in orange highlighted are our specialty technologies.

| Acylation | Acid chloride, acid anhydride, etc. |

|---|---|

| Amidation | Ammonia, amines, etc. |

| Amination | By reduction of nitro and nitroso, and by using amines |

| Alkylation | Dialkyl sulfuric acid, alkyl halide, etc. |

| Esterification | Various organic and inorganic acids, and alcohol |

| Reduction | By catalytic hydrogenation, using NaBH4, sulfurous acid, etc. |

| Grignard reaction | |

| Chlorination | NaOCl, SOCl2, PCl3, POCl3, etc. |

| Enantiomer synthesis | Asymmetric reduction, Optical resolution |

| Enzymatic reaction | Asymmetric hydrolysis, hydrolysis |

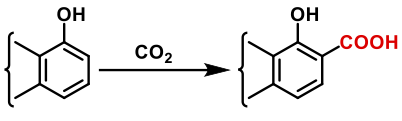

| Kolbe-Schmitt reaction | Carbon dioxide |

| Oxidation | Using H2O2, NaOCl, etc. |

| Diazotization | NaNO2 |

| Cyanation | -CONH2 → -CN |

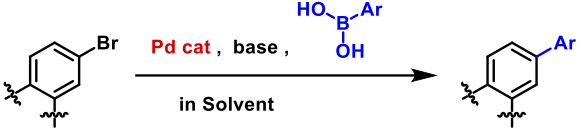

| Suzuki-Miyaura coupling | R-B(OH)2, Pd/C |

| Sulfonation | Sulfuric acid, fuming sulfuric acid, sulfur trioxide-pyridine complex |

| Nitration | Nitric acid, mixed acid, etc. |

| Nitrosation | NaNO2 |

| Glycosidation | BF3, methanesulfonic acid |

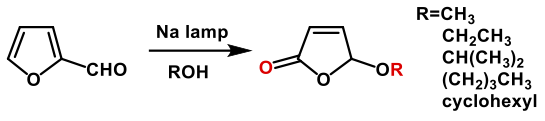

| Photo-oxidation | Sodium lamp |

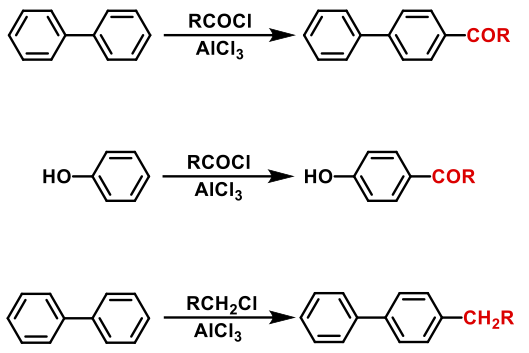

| Friedel–Crafts reaction | Acylation, Alkylating |

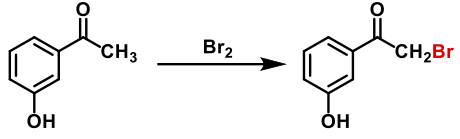

| Bromination | Br2 |

| Formylation | HCHO, Vilsmeier reaction, etc. |

| Mitsunobu reaction | |

| Phosphorylation | POCl3, PCl3 |

| Other organic synthesis reactions |

Our technology

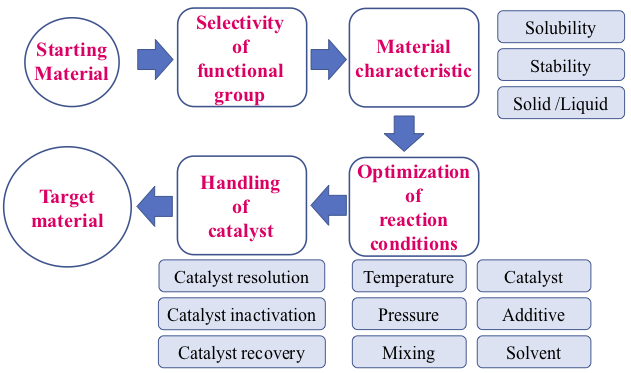

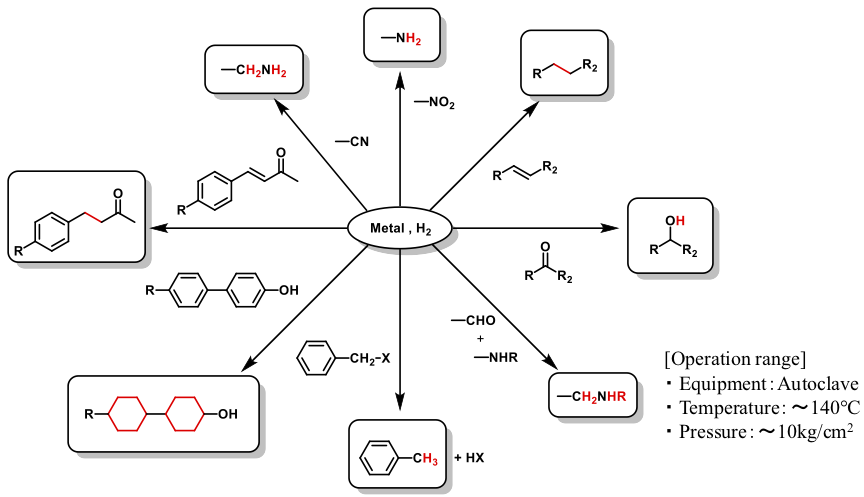

Catalytic reduction

We have well knowledge and many experiences of actual production relating to catalytic reduction.

We will select and provide the best reduction condition based on customer’s reaction.

In addition, we have established safe and reliable handling operations from charging to recovery.

We have also realized cost reduction through recycling in collaboration with catalyst manufacturers.

We will select and provide the best reduction condition based on customer’s reaction.

In addition, we have established safe and reliable handling operations from charging to recovery.

We have also realized cost reduction through recycling in collaboration with catalyst manufacturers.

|

| Example of catalytic reduction |

|---|

|

| Photo-Oxidation | Bromination | |

|---|---|---|

|

We have bromine tank system, so we can use bromine itself.

|

|

| Friedel-Crafts Reaction | Kolbe-Schmitt Reaction | |

| We use Aluminum Chloride. We have know-how on removing by-produced Aluminum Hydrochloride.  |

Reaction can be made under mild condition.

|

|

| Suzuki-Miyaura Coupling | ||

We can manufacture in actual equipment based on know-how regarding the use of Pd catalyst.

|

Inquiries About Service

Contact USpage top